Systems for transporting or ventilation of different media

Fluid lines in a vehicle are pipes or hoses that are used to transport various types of fluids within the vehicle. With the NORMAFLEX® Fluid Lines NORMA Group offers a comprehensive solution of original equipment products for the automotive aftermarket.

The advantages for garages are obvious:

- Easy parts identification

- Highest fitting accuracy

- Simple installation without special tools

- Einfache Montage ohne Spezialwerkzeuge

- Best original equipment quality at reasonable prices

OE Quality for the Automotive Aftermarket

NORMA has the right fluid line in original equipment manufacturer quality for every application in its range.

What are fluid lines?

Fluid lines in a motor vehicle are complete systems that are used to transport various types of fluids or even air within the vehicle. These include water/coolant, fuel, oil, brake fluid and other media.

How are fluid lines designed?

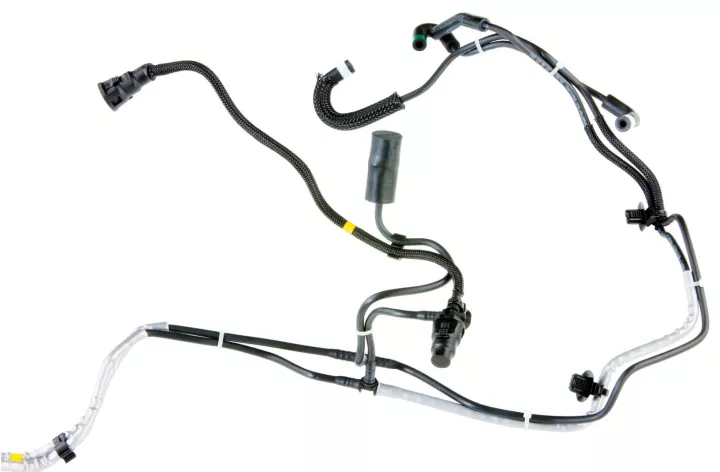

As a transport system for liquids or air, fluid lines consist of a plastic pipe or hose and corresponding connectors, also called quick connectors or quick couplers. These are used to connect and fix the fluid line to the corresponding components in the vehicle. Quick connectors are usually plugged onto a spigot and then snap into place. The pipe or hose and the connector are attached to each other by a spigot or a glued or laser welded connection. It is also possible to fasten the two components with a hose clamp.

In addition to these relatively simple fluid line designs, the automotive industry also uses very complex complete systems with numerous features and system integrations such as sensors and brackets.

NORMAFLEX®

Fluid Lines

Indispensable in modern vehicles.

Fluid lines play a crucial role in automotive technology, as they are responsible for the correct transport of the media or the ventilation of these.

Where are fluid lines used in vehicles?

Fluid lines are used in numerous applications. For example:

- Cooling Systems

- Fuel Supply

- Air Flow Systems

- Oil Transport Systems

- Crankcase Ventilation System

- Intake Pipes for the Compressor

The material composition varies depending on the area of application.

What properties characterize fluid lines from NORMA?

We have the right fluid line for every application in our range. All products are ready to use and impress with easy assembly and disassembly without special tools or accessories. NORMA fluid lines are also characterized by their chemical resistance to aggressive media such as oil or fuel.

When developing our fluid lines, we focus on keeping their weight as low as possible. And because the high quality standards of the car manufacturers are also our standards, you can rely on products in the best OE quality.

Our products are integrated into the TecDoc catalog, so identifying the right parts is a breeze.

This speaks for NORMA

As a long-standing original equipment manufacturer (OEM) for various car manufacturers, we produce strictly according to the standards of the automotive industry. For drivers and workshops, this means: spare parts in OE quality, which guarantee 100 percent accuracy of fit, quality and durability. And that at absolutely competitive prices.

Advantages at a glance

Original Equipment Quality

We are original equipment supplier to leading vehicle manufacturers. You therefore receive spare parts in the best OE quality.

Accuracy of fit

The original equipment manufacturer quality guarantees optimal fit and thus worry-free installation of the spare parts.

Easy Part Identification

Since our aftermarket products are listed in TecDoc, they can be identified quickly and easily.

Fast Assembly

Thanks to the quick connectors, our fluid lines can be easily assembled and disassembled without special tools.

Aftermarket Availability

Our product range is available from leading suppliers in the parts trade and is available at short notice.

Competitive Prices

Thanks to our aftermarket products, you get 100% OE quality at the attractive conditions of the free market.

When do fluid lines need to be replaced?

The exact service life of fluid lines in a vehicle depends on various factors. Of course, the type of line, its area of use and other parameters such as environmental conditions play an important role.

There are some general guidelines and signs that may indicate that fluid lines need to be replaced:

Visible damage

Inspect the lines for cracks, leaks, dents, or other visible damage. If such problems are found, replacement is necessary.

Age and mileage

As the vehicle ages and the mileage increases, fluid lines tend to wear out. Manufacturers may also recommend in their maintenance guidelines that lines be checked or replaced after a certain mileage.

Malfunctions

If there are signs of malfunctions in the system, such as difficulty braking or leaks, defective fluid lines may be the cause.

Rubber materials

In older vehicles, rubber lines can become brittle over time. If the lines become brittle or show signs of cracking, they should be replaced.

Fluid loss

An obvious loss of fluid in one of the systems (brakes, cooling system, power steering, etc.) is a clear sign that a line may be leaking.

Marten bite

If a marten is causing trouble in the vehicle, fluid lines are often damaged and leaks or malfunctions occur.

Accident damage

It is not uncommon for individual fluid lines, for example in the area of the radiator, to be damaged in an accident. In this case, the repair shop will replace the line.

In many cases, replacement is the safest and most reliable solution, especially when it comes to safety-relevant components such as brakes. Automotive professionals should make sure to use OE parts and spare parts in OE quality to ensure accuracy of fit, quality and durability.

It is important to note that regular maintenance and inspections can allow for the early replacement of worn or damaged fluid lines before more serious problems occur. The manufacturer's specifications and maintenance schedules should always be observed.

Did you already know?

Fluid lines from NORMA are also playing an increasingly important role in electrified powertrains. For example, in the area of water cooling for electric motors, cooling of the high-voltage battery module or cooling systems for power electronics.